CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

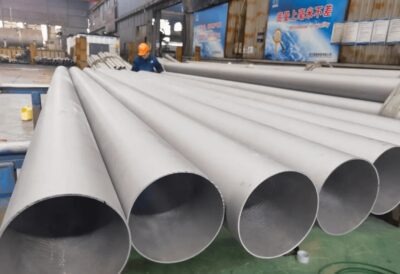

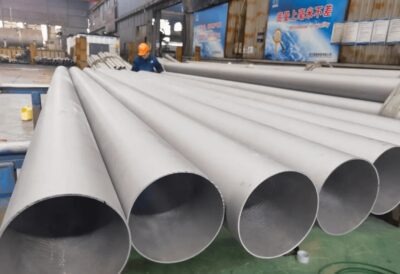

ASMESA312TP347H stainless steel welded pipe, as a bright pearl in the field of high-end stainless steel materials, with its excellent performance and a wide range of application fields, plays an indispensable role in petroleum, chemical, nuclear power, aerospace and other key industries. This paper will analyze the unique charm of ASMESA312TP347H stainless steel welded pipe from the aspects of its material characteristics, manufacturing process, application field, performance advantages and future development trend.

SA312TP347H stainless steel welded steel pipe

The material shall comply with the requirements of TSG D7002 pressure piping element type test Code.

ASME SA-312/SA-312M Specification for seamless, welded and cryogenically processed austenitic stainless steel pipes

ASMESA312TP347H stainless steel welded pipe chemical composition: carbon: 0.04~0.10, Silicon: ≤1.0, manganese: ≤2.0, phosphorus: ≤0.040, sulfur: ≤0.030, nickel: 9.00~12.00, Chromium: 17.00~19.00,

Common specifications: Outer diameter 57mm~1626mm, wall thickness 1.2mm~60mm.

Material properties analysis

ASMESA312TP347H stainless steel welded pipe, belonging to the austenitic stainless steel series, is based on 347 stainless steel by adding a small amount of niobium element (Nb) to strengthen the improvement. This improvement not only retains the good corrosion resistance and weldability of 347 stainless steel, but also significantly improves its strength and creep resistance in high temperature environments. In the chemical composition of TP347H, the chromium (Cr) content is about 18%-20%, the nickel (Ni) content is about 9%-12%, and the appropriate amount of niobium (Nb), molybdenum (Mo) and other elements constitute its unique alloy system. This alloy structure enables TP347H stainless steel welded pipe to maintain high mechanical strength and excellent oxidation resistance in the high temperature range of 600°C to 800°C.

### Manufacturing process overview

The manufacturing process of ASMESA312TP347H stainless steel welded pipe strictly follows international standards and adopts advanced production processes and technologies. First of all, the selection of high-quality raw materials for smelting, to ensure the accuracy and uniformity of alloy composition. The billets are then processed into tubes of the required specifications by a hot or cold rolling process. In the welding process, the use of advanced automatic welding equipment and technology to ensure that the quality of the weld meets or even exceeds the standard requirements. After the welding is completed, it is also necessary to conduct strict heat treatment to eliminate welding stress and improve the overall performance of the pipe. Finally, through strict dimensional inspection, mechanical property testing, non-destructive testing and other quality control processes, to ensure that each welded pipe can meet the strict requirements of customers.

### Wide range of applications

ASMESA312TP347H stainless steel welded pipe is widely used in many key fields because of its excellent performance. In the petrochemical industry, as a high temperature and high pressure pipeline material, it can withstand extreme working environments to ensure the safety and efficiency of oil and gas transportation. In the field of nuclear power, TP347H stainless steel welded pipe is used in the cooling system of nuclear reactors, and its excellent high temperature resistance and corrosion resistance can provide a solid guarantee for the safe operation of nuclear power plants. In addition, in the aerospace, heat exchanger, boiler manufacturing and other fields, TP347H stainless steel welded pipe also plays an irreplaceable role.

Significant performance advantages

Compared to other types of stainless steel welded pipes, ASMESA312TP347H stainless steel welded pipes show significant performance advantages in the following aspects:

1. ** High temperature strength ** : Under high temperature environment, TP347H can still maintain high mechanical strength and is not easy to creep or soften.

2. ** Oxidation resistance ** : Its excellent oxidation resistance enables the welded pipe to run stably for a long time at high temperature, reducing the performance decline caused by oxidation.

3. ** Corrosion resistance ** : Good corrosion resistance, so that the welded pipe can resist the erosion of a variety of corrosive media, extend the service life.

4. ** Good weldability ** : By adding niobium, TP347H stainless steel welded pipe is not easy to produce hot cracks in the welding process, and the welding quality is more reliable.

5. ** Excellent processing performance ** : easy to process into various shapes and sizes to meet different engineering needs.

In short, ASMESA312TP347H stainless steel welded pipe as a high-performance stainless steel material, with its excellent performance and a wide range of application fields, occupies an important position in the high-end stainless steel material market. In the future, with the continuous progress of technology and the continuous expansion of the market, TP347H stainless steel welded pipe will usher in a broader development prospect.