CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

Before exploring ASMESA358 304 stainless steel pipe in depth, we first need to have a comprehensive understanding of the materials science, industrial applications, manufacturing processes and performance characteristics behind it.ASMESA358 standard, as the American Society for Testing and Materials (ASTM) for seamless and welded austenitic stainless steel pressure piping to develop an important specification for the 304 stainless steel pipes under the standard because of its Excellent corrosion resistance and a wide range of applications and is highly regarded.

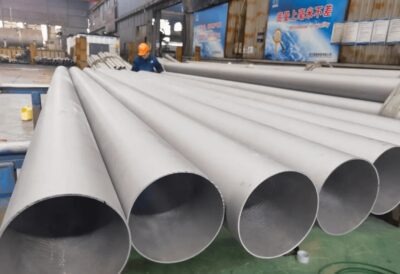

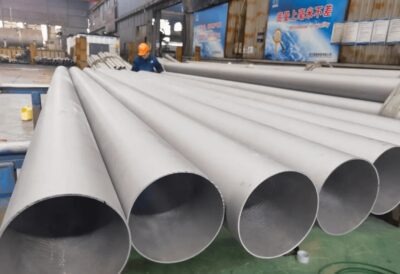

SA358 304 stainless steel welded steel pipe

The products shall comply with the requirements of TSG D7002 Type Test Rules for Pressure Piping Components.

ASME SA-358/SA358M high temperature and general purpose electrofusion welded chromium-nickel austenitic stainless steel pipe specification.

ASMESA358 304 stainless steel pipe chemical composition: carbon: ≤ 0.08, silicon: ≤ 1.0, manganese: ≤ 2.0, phosphorus: ≤ 0.040, sulfur: ≤ 0.030, nickel: 8.0 ~ 11.00, chromium: 18.00 ~ 20.00

Common specifications: OD 57mm~1626mm, wall thickness 1.2mm~60mm.

Production method: welding, delivery status: heat treatment + pickling.

Material Science and Chemical Composition

Stainless steel 304, also known as 18/8 stainless steel, is named for the fact that it contains approximately 18% chromium (Cr) and 8% nickel (Ni). These two elements are key to forming the corrosion resistance of stainless steel. Chromium forms a dense film of chromium oxide on the surface of the steel, effectively preventing further attack by oxygen and water, while nickel improves the corrosion resistance of stainless steel and enhances its strength at high temperatures. In addition, 304 stainless steel may also contain small amounts of carbon (C), silicon (Si), manganese (Mn), phosphorus (P) and sulfur (S) and other elements to regulate its physical and mechanical properties.

The 304 stainless steel pipe under ASMESA358 standard not only requires the chemical composition to be in accordance with the specified range, but also has strict requirements on its internal quality, surface finish, dimensional accuracy, etc. to ensure the stability and reliability of the pipe in a variety of working conditions.

### Industrial Applications

ASMESA358 304 Stainless Steel Tubing is widely used in several industrial fields due to its excellent corrosion resistance, good processing performance and high strength. In the chemical industry, it is often used to transport corrosive liquids and gases, such as acids, alkalis, salt solutions, etc.; in the field of food processing and pharmaceuticals, its non-toxic, odorless, easy-to-clean characteristics make it an ideal material for manufacturing equipment and pipelines; in addition, in the petroleum, natural gas, water treatment, papermaking, textile and other industries, you can also see the 304 stainless steel pipe.

It is especially worth mentioning that in nuclear energy, aerospace and other high-tech fields, the requirements for materials are even more stringent, and ASMESA358 304 stainless steel pipe has become an important part of these fields due to its excellent comprehensive performance.

### Manufacturing process

The manufacturing process of ASMESA358 304 stainless steel pipe involves a number of key steps, including raw material preparation, melting, casting, hot rolling, cold rolling (or cold-drawing), heat treatment, pickling, polishing, inspection and packaging. Among them, the melting process requires strict control of chemical composition and impurity content; hot rolling and cold rolling determine the dimensional accuracy and surface quality of the pipe; while heat treatment adjusts the organizational structure of the steel pipe and improves its mechanical properties and corrosion resistance through heating and cooling.

It is worth mentioning that the ASMESA358 standard has more stringent regulations for welded steel pipes, requiring that welds must be thoroughly tested to ensure their strength and sealing. Common welding methods include TIG (Tungsten Inert Gas Shielded Welding), MIG (Melting Inert Gas Shielded Welding) and SAW (Submerged Arc Welding).

### Performance characteristics

1. **Corrosion resistance**: As mentioned earlier, 304 stainless steel has excellent corrosion resistance due to its high chromium and high nickel chemical composition, able to resist the erosion of a variety of chemical media.

2. **Mechanical Properties**: ASMESA358 304 stainless steel pipe has good tensile strength, yield strength and elongation, and can withstand a certain amount of pressure and impact loads.

3. **Processing Properties**: The material is easy to cut, bend, weld and mold, facilitating the processing into a variety of complex shapes of pipes and components.

4. **Hygienic**: Non-toxic, odorless, and non-bacterial, it is ideal for use in industries requiring high hygiene standards, such as food processing and pharmaceuticals.

5. **Aesthetics**: After polishing treatment, the surface of 304 stainless steel pipe is as bright as a mirror, with good decorative effect.

### Maintenance and care

Although ASMESA358 304 stainless steel pipe has excellent corrosion resistance, it still requires attention to maintenance and care during use. Regular cleaning of the inner and outer walls of the pipe to remove adhering dirt and corrosion products is an important measure to maintain its good performance. In addition, avoid the use of cleaning agents containing chloride ions or long-term immersion in a chlorine-containing environment to prevent pitting or stress corrosion cracking.

### Conclusion

To summarize, ASMESA358 304 stainless steel pipe has become an indispensable and important material in modern industry by virtue of its excellent performance characteristics and wide range of applications. With the progress of science and technology and the continuous improvement of the process, we have reason to believe that in the future development, ASMESA358 304 stainless steel pipe will continue to play its unique advantages, contributing to the development of various industries. At the same time, we also need to keep learning and exploring to better master and apply this important material.