CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

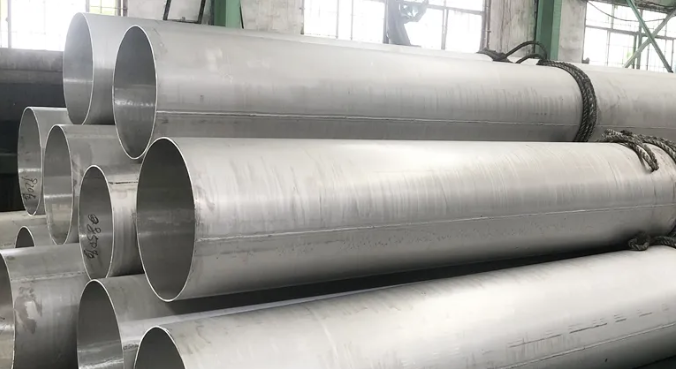

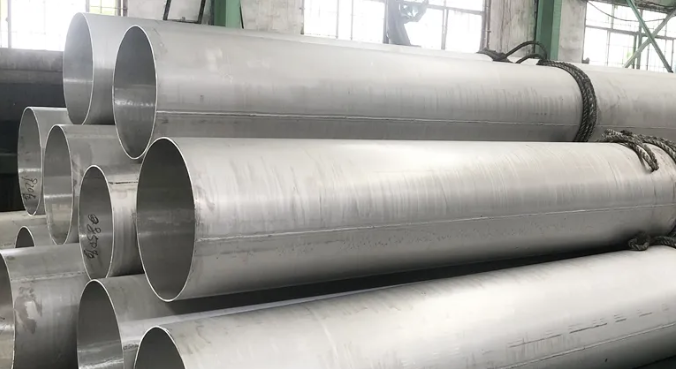

ASMESA249TP304H stainless steel welded pipe, as a high-performance and multi-purpose pipe in the industrial field, its unique material characteristics and a wide range of application fields, making it play a pivotal role in many engineering projects. In this paper, the material characteristics, production process, application field, quality control and future development trend of ASMESA249TP304H stainless steel welded pipe will be elaborated in detail, in order to provide readers with a comprehensive and in-depth understanding.

ASMESA249TP304H stainless steel welded steel pipe

Specification for welded austenitic steel tubes for boilers, superheaters, heat exchangers and condensers

The product shall comply with the requirements of TSG D7002 pressure pipeline element type test rules.

Chemical composition of TP304H stainless steel welded pipe: carbon C: ≤0.040~0.10, Manganese Mn ≤2.0, Phosphorus p: ≤0.045, sulfur S: ≤0.030, Silicon Si ≤1.00, nickel Ni 8.00-11.00, Chromium Cr: 18.00-20.00

Product specifications: Outer diameter 57mm~114mm, wall thickness 1.2~3.0

Production method: welding, delivery status: Heat treatment + instant-boiled.

### Material characteristics

ASMESA249TP304H stainless steel welded pipe, belongs to the austenitic stainless steel series, is a high temperature strengthened version of 304 stainless steel. Its main chemical composition includes chromium (Cr), nickel (Ni) and trace amounts of titanium (Ti) or niobium (Nb), which together give TP304H stainless steel excellent corrosion resistance and high temperature strength. Specifically, the material performs well in oxidizing environments, can resist the erosion of a variety of chemical substances, and at the same time, it can maintain high mechanical properties and stability at high temperatures (up to 550°C or more), which is the ideal material for high temperature and high pressure environments such as petroleum, chemical, electric power, nuclear energy.

### Production process

The production process of ASMESA249TP304H stainless steel welded pipe is complex and fine, mainly including raw material preparation, forming, welding, heat treatment, pickling passivation, inspection and packaging. In terms of raw materials, high-quality stainless steel plates or steel strips should be selected, and strict chemical composition analysis and physical property testing should be carried out to ensure that the quality of raw materials meets the standards. In the molding process, the steel plate or steel strip is usually processed into a tube by coil forming method or extrusion forming method. The welding process is the core, using advanced TIG (tungsten inert gas welding) or MIG (metal inert gas welding) technology to ensure the quality of the weld, while avoiding oxidation and cracking during the welding process. Heat treatment is a key step to improve the high temperature performance of the pipe. Through solid solution treatment and stabilization treatment, welding stress is eliminated, organizational structure is optimized, and corrosion resistance and high temperature strength of the pipe are improved. Finally, after strict pickling passivation treatment, the surface oxidation and welding residue are removed to improve the surface finish and corrosion resistance of the pipe.

### Quality control

Quality control is the key to ensure the stability, safety and reliability of ASMESA249TP304H stainless steel welded pipe. From raw materials into the factory to finished products, every link needs to go through strict quality testing and control. Raw materials shall be subjected to chemical composition analysis, mechanical property testing, surface quality inspection, etc. In the production process, it is necessary to monitor the key process parameters such as welding parameters, heat treatment temperature and time in real time; The finished product is subject to visual inspection, dimensional measurement, hydrostatic testing, non-destructive testing (such as X-ray inspection, ultrasonic inspection), as well as chemical composition and mechanical properties retesting. In addition, some high-end applications also require intergranular corrosion sensitivity tests and high temperature endurance strength tests for pipes to further verify their performance.

### Future development trend

With the continuous advancement of global industrialization and the rapid development of technology, the market demand for ASMESA249TP304H stainless steel welded pipe will continue to grow. Especially in new energy, environmental protection, aerospace and other emerging fields, the demand for high-performance, high-reliability materials is growing, providing a broad space for the development of TP304H stainless steel welded pipe. In the future, with the continuous progress of material science and the optimization and upgrading of the production process, the performance of TP304H stainless steel welded pipe will be further improved, the cost will be further reduced, and the application field will be more extensive. At the same time, with the increasingly frequent international trade and the intensification of global competition, improving product quality, strengthening brand building, and expanding the international market will become an important development direction of TP304H stainless steel welded pipe manufacturers.