CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

Ball valves are evolved from plug valves. It has the same opening and closing action, the difference is that the spool rotating body is not a plug but a sphere. When the ball is rotated 90 degrees, it should all be spherical at the inlet and outlet, thus cutting off the flow.

Classification by structure

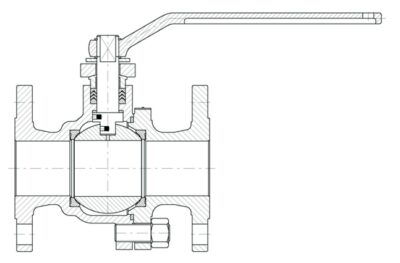

Floating ball valve

The floating ball valve is widely used because of its simple structure and low price, and is generally used in the range of nominal size not greater than DN200.Ball valves with smaller nominal sizes are generally opened or closed using a wrench or lever.Due to the large opening and closing torque of the ball valve with larger nominal size, the worm gear is usually used to open or close the valve.

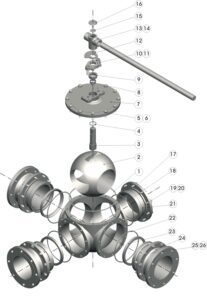

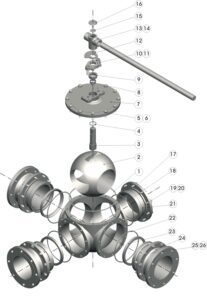

Three-way floating ball valve

L-shaped three-way ball valve (Q44)

It is used to switch the flow direction of the medium in the pipeline, so that two vertical flow channels can be connected.

T-shaped three-way ball valve (Q45)

It can be used for the diversion, confluence and flow direction switch of the medium, and the T-shaped ball channel can make the three channels connected with each other or make two of the channels connected, and the T-shaped ball valve can achieve two, three or four functions of them.

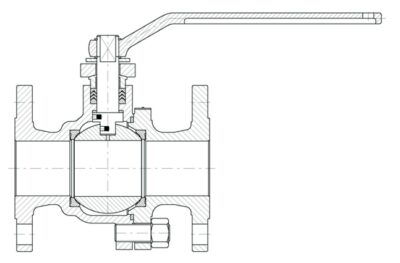

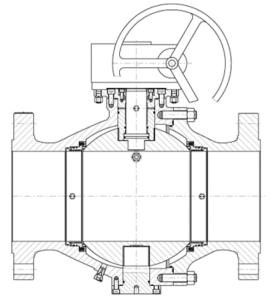

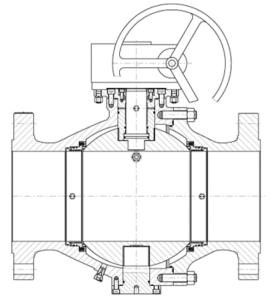

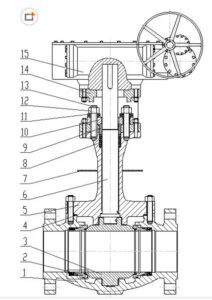

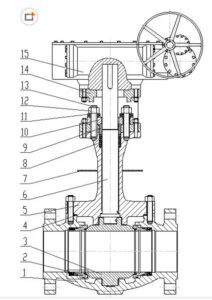

Fixed ball valve

Compared with floating ball valves, fixed ball valves are suitable for large diameters and high pressures. The structure of the fixed ball valve is more complex than that of the floating ball valve, and the cost and price are higher.

Generally, the torque of fixed ball valves of the same caliber is smaller than that of floating ball valves.

The ball of the fixed ball valve only rotates and does not move during the switching process, and the valve seat will stick to the ball under the action of the spring and the medium force, so that the ball and the valve seat are sealed. The spring force and the medium force can be controlled.

temperature-wise

Ball valve with insulated jacket

For conditions where the medium is easy to crystallize, it is usually necessary to use the thermal insulation jacket ball valve to prevent the crystallization of the medium flowing through the ball valve by passing steam and other thermal insulation media in the jacket.

Low temperature ball valve

In order to prevent stem packing seal failure under low temperature conditions, low temperature ball valve adopts long neck structure design. The valve seat is designed with automatic pressure relief function to prevent abnormal pressure increase due to temperature rise of the medium in the valve cavity

LNG valve types

Top ball valve

The top type valve body structure is designed, and the valve seat is sealed by spring compression piston effect. The ball and valve seat can be removed from the middle cavity flange to realize online maintenance.

DBB structure: Both inlet and outlet ends are single pistons

DIB-1 structure: Both the inlet and outlet ends are double pistons

DIB-2 structure: The inlet end is a single piston, and the outlet end is a double piston

Material selection

With the rapid development of LNG, the application of ultra-low temperature valves is more and more extensive, and the use characteristics of the valves, the selection and treatment of materials are the key to ensure the performance of the valves at low temperatures. In the selection of materials used under low temperature conditions, the following two aspects should be considered:

(1) The material should have enough toughness under ultra-low temperature conditions to prevent brittle fracture;

(2) Under ultra-low temperature conditions, the material should have sufficient organizational stability to ensure that the sealing of the valve will not be affected by phase change to quality deformation at low temperatures.

Long neck valve cover structure

Due to the particularity of the ultra-low temperature valve medium, the structure of the ultra-low temperature valve is different from other valves.

In the low temperature state, with the increase of time, the elasticity of the packing will gradually decrease, therefore, the ultra-low temperature valve uses the long neck structure of the valve cover to raise the position of the packing to make the packing work in an environment above zero. The relationship between the size of the long neck of the valve cover and the diameter of the valve body is determined by calculation, analysis and test.

Regulating ball valve

The movable seat structure loaded by plate spring, the seat and the ball will not be stuck or separated, reliable sealing, long service life;The V-notched ball has a shearing effect with the metal seat, especially suitable for media containing fibers, small solid particles, and slurry.Large flow capacity, small fluid resistance.It can be used either as a regulator or as a cut-off.

Characteristics of ball valve

Ball valves are mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. It has the following advantages: