CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

Complete annealing, normalizing and quenching all belong to the heat treatment process of steel, but the purpose is not the same.

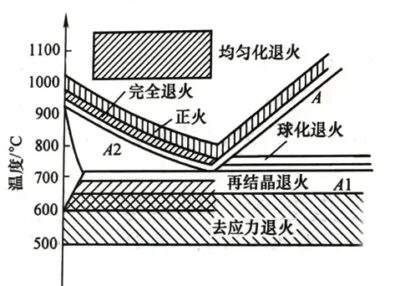

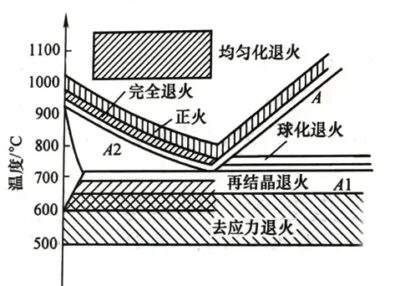

The temperature they reach before heating is almost the same, only the cooling method is different. The three heat treatment heating temperatures are shown in Figure 1.

Complete annealing heat treatment. The heating temperature is 20 to 30°C above AC3, completely austenitizing, and then slowly cooling to obtain a balanced structure. The structure has almost no dislocation, few solvable carbon atoms and little internal stress.

Therefore, the process is mainly used to improve the machining performance, but the low carbon steel with too low carbon content and the hypereutectoid steel with high carbon content are not suitable for this heat treatment method. Because the carbon content is too low, the steel is extremely soft after complete annealing, which is not conducive to cutting. The carbon content is too high, because of the slow cooling rate of the annealing method, it is easy to form a network cementite in the grain boundary, making the material brittle.

On the other hand, complete annealing heat treatment through recrystallization, can refine the grain, eliminate ribbon structure and segregation.

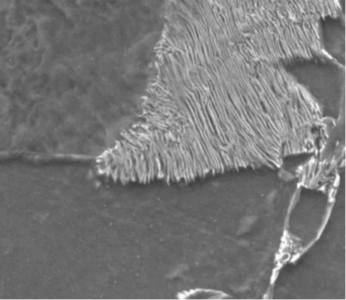

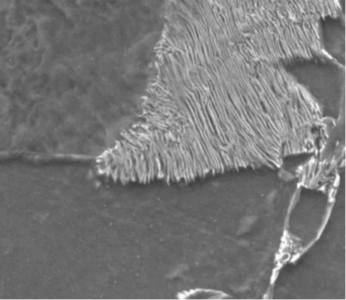

Hot processing. The heating temperature is similar to that of full annealing. After holding for a period of time, it is cooled in the air to obtain tissues containing pearlite. Figure 2 shows the normalizing structure of hypoeutectoid steel, consisting of ferrite and pearlite.

Obviously, the cooling rate of normalizing is faster than that of complete annealing, and the obtained pearlite sheet is finer, and the strength and hardness are higher than that of complete annealing.

Normalizing can also be used as a preparatory heat treatment to improve the cutting performance, refine the grain and homogenize the structure. For some occasions with low performance requirements, it can be used as the final heat treatment.

Quenching heat treatment. After the steel is heated to austenitizing, it is kept warm for a period of time, and then placed in the liquid cooling medium for rapid cooling, greater than the critical speed, and finally martensitic structure is obtained, as shown in Figure 3. More carbon atoms are solidly dissolved in martensite, which greatly improves the strength and hardness. Quenching is often used in conjunction with tempering, so that the material obtains comprehensive excellent mechanical properties. Such as the use of a wide range of tempering heat treatment, is quenching and high temperature tempering.

More carbon atoms are solidly dissolved in martensite, which greatly improves the strength and hardness.

What are the similarities and differences between complete annealing, normalizing and quenching of steel? The heating temperature of the three is almost the same, and they all have to go through austenitizing, the only difference is the cooling speed. Complete annealing is slow cooling with the furnace, normalizing is air cooling, quenching is cooling in liquid, such as water, oil and other media. Bearing in mind the different cooling methods of the three heat treatments, it is easy to distinguish.