CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

Corrosion prevention of steel pipes is very common in our daily use!

Anti-corrosion insulation steel pipe

Corrosion prevention is generally composed of 3 layers: the first layer of epoxy powder (FBE>100um), the second layer of adhesive (AD)170 ~ 250um, the third layer of polyethylene (PE)2.5 ~ 3.7mm. In actual operation, the three materials are mixed into one, and after processing, they are firmly combined with the steel pipe to form an excellent anti-corrosion layer. Its processing methods are generally divided winding type and circular die coating type.

Ordinary steel pipe in the use of harsh environment, there will be serious corrosion, which will reduce the service life of the steel pipe, anti-corrosion insulation steel pipe service life is also relatively long, generally can be used for 30-50 years or so, and the correct installation and use can also make the pipe network maintenance costs lower, anti-corrosion insulation steel pipe can also be set alarm system, Automatic detection of pipe network leakage fault, accurate knowledge of the fault location and automatic alarm.

Anti-corrosion insulation steel pipe insulation performance is good, the heat loss is only 25% of the traditional pipe, long-term operation can still save relatively large resources, significantly reduce energy costs, and still has a relatively strong waterproof and corrosion resistance, and does not need to be attached to the pipe trench, directly can be buried in the ground or water, in the construction is also simple and rapid, The comprehensive cost is also relatively low, it also has good corrosion resistance and impact resistance under low temperature conditions, and it can also be directly buried in frozen soil in a certain environment.

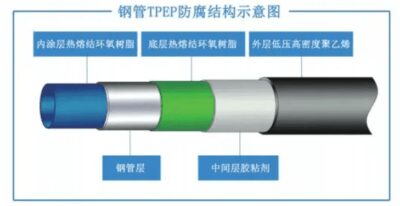

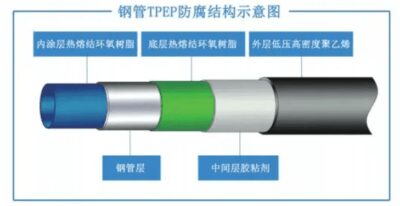

TPEP anti-corrosion steel pipe (inner fused epoxy outer 3PE anti-corrosion steel pipe)

The full name of TPEP anticorrosive steel pipe is “inner fused epoxy outer 3PE anticorrosive steel pipe”. The steel pipe is used as the base material, and the inner wall of the pipe is made of hot fused epoxy powder anticorrosive method. The powder is uniformly coated on the surface of the pipe body after high temperature heating and melting to form a steel-plastic alloy layer. TPEP anti-corrosion steel pipe is an upgraded product based on the outer single-layer polyethylene and the inner epoxy composite steel pipe, which is the fourth generation of new anti-corrosion production process.

Inner wall hot melt bonded epoxy coating thickness (:>0.4mm) : chemical corrosion resistance, cathode stripping resistance, smooth, environmental protection.

The first layer of epoxy powder (> 120um) : resistant to chemical corrosion and cathode stripping.

The second layer of adhesive (Mr 170um) : the bonding effect of the bottom layer of epoxy and the outer layer of polyethylene.

The third layer of polyethylene (2.2 ~ 3.7mm) : mechanical protection, anti-corrosion.

TPEP composite coating: polyethylene and epoxy have excellent corrosion resistance, polyethylene is a thermoplastic material, good flexibility, bump resistance. Epoxy resin is a polar molecule, has a hydroxyl group, at a certain temperature, easy to react with the steel pipe, strong adhesion. Therefore, the combination of the two materials is the best match in the current anti-corrosion industry.

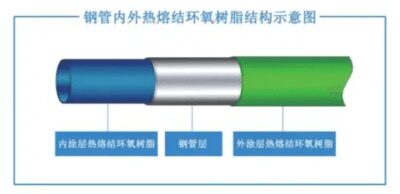

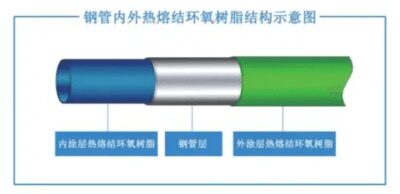

Plastic coated composite steel pipe (inside and outside fused epoxy)

The product is marked as T(EP-EP), the product is based on steel pipe, the internal and external coatings are epoxy resin, through the steel pipe heating, powder spraying process in the internal and external surface melting to form the anti-corrosion layer.