CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

As an important high-temperature structural steel material, P235GH seamless steel pipe plays a pivotal role in the modern industrial field. With its excellent mechanical properties, corrosion resistance, welding properties and processing properties, it has become the preferred material for petrochemical, chemical, electric power and other industries. This article will discuss the manufacturing process, characteristics and application fields of P235GH seamless steel pipe in detail, in order to show its wide use and excellent performance in modern industry.

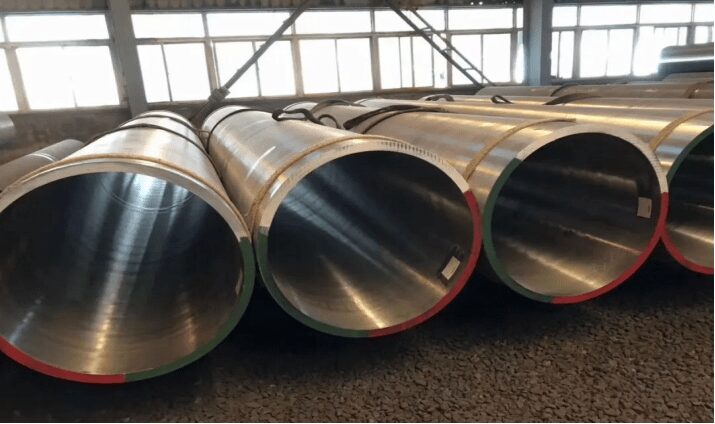

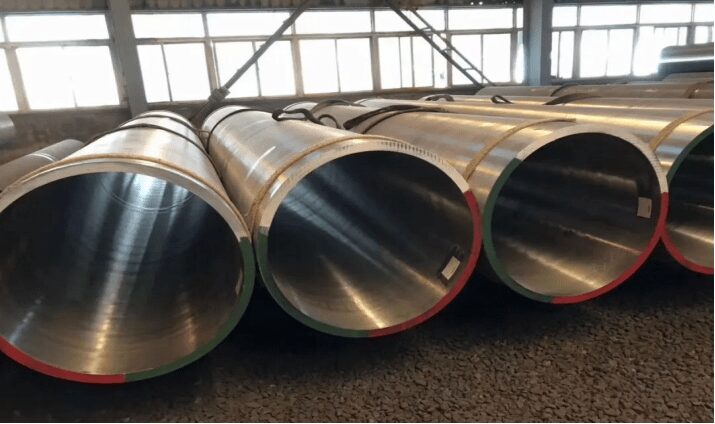

P235GH seamless pipe P235GH seamless pipe

BS EN 10216-2 Seamless steel tubes for pressure applications – Technical delivery conditions – Part 2: Non-alloy and alloy steel tubes with specified high temperature characteristics

The product shall comply with TSG D7002 pressure pipeline element type test rules.

P235GH seamless steel pipe chemical composition: carbon: ≤0.16, silicon: ≤0.35, manganese: ≤1.20, phosphorus: ≤0.025, sulfur: ≤0.020, chromium: ≤0.30, molybdenum: ≤0.08, nickel: ≤0.30, aluminum: ≥0.020, copper: ≤0.30, niobium: ≤0.010, titanium: 0.0410, vanadium: ≤0.02, chromium + copper + molybdenum + nickel: ≤0.70

Product specifications: Outer diameter 21.3mm~1016mm, wall thickness 2.0~140mm.

The product shall comply with TSG D7002 pressure pipeline element type test rules.

The manufacturing process of P235GH seamless steel pipes strictly follows a series of elaborate process steps. First of all, the selection of high-quality low carbon steel or alloy steel as raw materials, through continuous casting or rolling and other processes to obtain suitable steel. Subsequently, the steel is also heated at high temperature in the heating furnace to ensure that the steel also reaches the appropriate hot rolling temperature. After entering the hot rolling process, the steel is still under the strong pressure of the rolling mill, and after several extrusions and stretches, it gradually deforms and forms the initial shape of the seamless steel pipe. After the completion of hot rolling, the seamless steel pipe needs to be heat treated to eliminate internal stress, improve organizational structure and improve performance. In the heat treatment process, by controlling the heating temperature, holding time and cooling rate and other parameters, the seamless steel pipe can achieve the best performance state.

In the manufacturing process of seamless steel pipe, quality control is a crucial part. In the production process, the manufacturer will strictly implement the relevant standards and specifications to ensure that the chemical composition, mechanical properties, dimensional accuracy and other aspects of the seamless steel pipe meet the requirements. At the same time, every link in the production process is strictly monitored and tested to ensure that the quality of seamless steel pipes is stable and reliable.

In addition, P235GH seamless steel pipe also has good welding performance and processing performance. The strength and toughness of the weld can meet the requirements of the base material, making the seamless steel pipe easy to connect and process in the manufacturing process. This excellent processing performance makes P235GH seamless steel pipe can be customized according to actual needs, to meet the needs of a variety of complex structures and equipment. In the field of application, P235GH seamless steel pipe is widely used in petrochemical, chemical, electric power, heat and other industries.

In the petrochemical industry, P235GH seamless steel pipes are used to manufacture reactors and pipes under high temperature and pressure, which can withstand the erosion of high temperature and pressure and corrosive media.

P235GH seamless steel pipe is widely used in many industrial fields, thanks to its excellent characteristics. First of all, P235GH steel plate has high strength and plasticity, which can meet the requirements of use under complex stress conditions. This enables P235GH seamless steel pipe to maintain stable performance under harsh environments such as high pressure and high temperature. Secondly, P235GH seamless steel pipe has excellent corrosion resistance, and can still maintain good corrosion resistance and stability in acidic, alkaline, salt solution and other corrosive environments. This feature makes P235GH seamless steel pipe have a wide range of application prospects in chemical, petroleum and other industries.