CURABITUR ALIQUET QUAM POSUERE

Welcome Aboard Us!

Subscribe to our emails for the latest industry updates and special offers.

Will be used in accordance with our Privay Policy

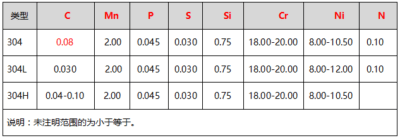

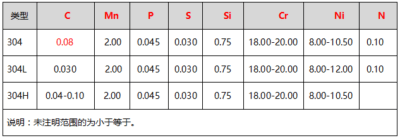

“304, 304L and 304H” are all grades of stainless steel, and they all belong to the 300 series austenitic stainless steel, which has similar chemical composition and physical properties.

In fact, according to the content of chromium nickel is 304 stainless steel, the composition is containing 18% chromium (Cr), 8% nickel (Ni), but the main difference is the difference in carbon content.

304L is an ultra-low carbon stainless steel, the carbon content is reduced to less than 0.03%, which can avoid intergranular corrosion, and the effect of stress corrosion resistance is stronger than 304 in theory, but the effect is not obvious in practical applications. The purpose of reducing carbon and adding titanium is the same, but the 321 smelting cost of titanium is higher, the molten steel is thick, and the price is more expensive.

The H in 304H refers to high temperature, high carbon content is the guarantee of high temperature strength, GB150 requires austenitic steel used above 525 degrees, the carbon content is not less than 0.04%, carbide is the strengthening phase, especially the high temperature strength is better than pure austenite.

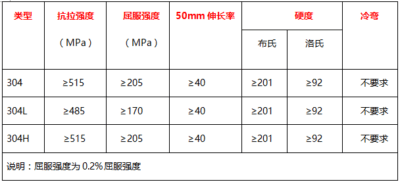

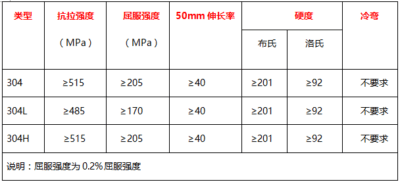

Among the three, the highest carbon content is 304H, the lowest carbon content is 304L, and the carbon content of 304 stainless steel is between the two. The higher the carbon content of stainless steel, the poorer the corrosion resistance and the easier it is to rust. The difference in carbon content also leads to its price will be different, or the use of different requirements are different.

In addition, from these two lists can be judged that the idea that 304L can replace 304 is wrong, can not be used and the use of the occasion, and according to the regulations, we have no right to carry out “material substitution”, only the original design department can have the right to carry out “material substitution” work, this point please remembe